I-chuck enamandla enemagnethi esisigxina, njengesixhobo esisebenzayo, esigcina amandla kunye nesixhobo esilula sokusebenza sokubamba izixhobo zokusebenza, isetyenziswa kakhulu kwiinkalo ezahlukeneyo ezifana nokusetyenzwa kwesinyithi, ukuhlanganisa, kunye nokuwelda. Ngokusebenzisa iimagnethi ezisisigxina ukubonelela ngamandla okufunxa okuzingisileyo, ikomityi yokufunxa imagnethi esisigxina iphucula kakhulu ukusebenza kakuhle kwemveliso, yonga ixesha kunye neendleko. Eli nqaku liza kubonelela ngentshayelelo eneenkcukacha kwimigaqo yobugcisa, izibonelelo zemveliso, uthintelo losetyenziso kunye neendlela zokugcinwa kwekomityi yokufunxa umazibuthe esisigxina, ukunceda abasebenzisi ukuba baqonde ngcono kwaye basebenzise esi sixhobo.

I. Umgaqo-siseko wobuGcisa we-Chuck yeMagnetic enamandla eSisigxina

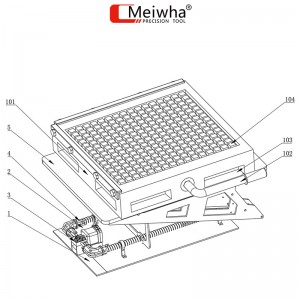

Chuck Umzobo wesakhiwo sangaphakathi

1.Uyilo oluphezulu lwemagnethi enemacala amathathu

- Ulwakhiwo lwepali yemagnethi enamaleko amabini:

I-double-layer magnetic circuit yenziwa ngokusebenzisa i-T-shaped core kunye ne-side-lying plate. I-Neodymium-iron-boron magnetic steel (ene-N pole oriented) kunye ne-aluminiyam-nickel-cobalt ephantsi yensimbi yentsimbi yenza iisekethe ezintathu ezizimeleyo ezivaliweyo. Imigca yamandla emagnethi ijikeleza isuka embindini → isixhobo sokusebenza → ipleyiti yangaphandle → ipleyiti esezantsi → undoqo, ngokwenjenjalo inyusa uxinano lwemagnethi ngaphezulu kwe-16%.

- Imagnethi egxile kumbindi:

I-core ye-T-shaped core iguqula imigca yemagnethi emaphethelweni ukuya embindini, ijongana nomba wokunganyaniseki okwaneleyo kwi-workpieces emxinwa (njengezikhokelo kunye nee-blades), kunye nobukhulu obuncinane bokusebenza obuhambelanayo bufikelela kwi-50 × 50 × 2mm.

2.Halbach Array Enhancement

- Uluhlu lwemagnethi olumilo olunqamlezileyo:

Imodeli ephezulu ithatha i-dimensional "cross" uhlobo lweHalbach array. Ngolungelelwaniso oluthile lweemagnethi ezisisigxina (ezineepali ze-NS ezijikelezayo ngokutshintshanayo), ikhokela ngokuzimeleyo isalathiso semagnethi, inyusa ingxinano yemagnethi kwelinye icala lendawo yokusebenza ngama-50% kwaye inciphisa ukuvuza kwamagnethi ngama-30%.

- UkuPhuculwa koMgangatho wokuSetyenziswa kwamandla eMazinethi:

Ngaphantsi komthamo ofanayo, uluhlu lweHalbach lunyusa uxinaniso lwamandla omagnetic ukusuka kwi-120N/cm² kuyilo lwemveli ukuya kwi-180N/cm², ngelixa inciphisa ukusetyenziswa kwezinto nge-20%.

| Uhlobo lwezinto eziphathekayo | indima ephambili | iparameter yokusebenza | iimeko zesicelo |

| NdFeB(neodymium iron boron) | Ukunyanzeliswa okuphezulu (≥ 955 kA / m) i-anti-demagnetization ikhono | Umazibuthe osisigxina Br = 1.26 - 1.29 T | I-pole enkulu yamagnetic iqinisekisa ukunamathela okuqinileyo. |

| I-Aluminiyam-nickel-cobalt | Imagnethi ephezulu eyintsalela (Br = 1.3T) yongeza amandla omhlaba wemagnethi | Ubushushu bokusebenza ≤ 460℃ | Ipoleni elincedisayo lamagnetic, liphucula ukuzinza kwe-thermal |

| LNG umazibuthe osisigxina | I-polarity eguquguqukayo, ephendula kwiimpawu zokulawula umbane | Amandla okugcina: 56 kA / m | Umaleko wokuphumeza wesekethe yemagnethi |

Impembelelo ye-Synergistic: I-NdFeB ibonelela ngesakhono sokuchasana ne-demagnetization, i-AlNiCo yonyusa amandla okungena kwintsimi yamagnetic, i-LNG yenza ukuba i-polarity iguqulwe. Ezi zinto zintathu zisusa umahluko onokwenzeka wemagnethi ngedyokhwe yemagnethi yesithinteli, iqinisekisa ukuba intsalela yemagnethi isondela ku-zero ngexesha le-demagnetization.

II. Izinto eziluncedo kwiMveliso ye-High-Intensity Permanent Magnetic Chuck

Meiwha CNC Chuck

1.Akukho mfuneko yomthombo wamandla wangaphandle

I-Chuck enezibuthe enamandla esisigxina ibonelela ngamandla okulungisa ngeemagnethi ezisisigxina kwaye ayifuni mbane. Kwezinye iindawo zokusebenza ezikude nemithombo yamandla okanye apho kungenakulungeleka khona ukusebenzisa umbane, i-chuck esisigxina yamagnetic inikeza isisombululo esilula kakhulu.

2.Ufakelo oluKhawuleza kunye nokuDisassembly

Xa kuthelekiswa nezinto ezilungiswayo zemveli okanye iikomityi zokufunxa zombane, ichuck enemagnethi esisigxina inofakelo olukhawulezayo kunye nesantya sokuqhawula. Ngomsebenzi olula nje, i-workpiece inokulungiswa okanye ikhululwe, ngaloo ndlela iphucula ukusebenza kakuhle komgca wemveliso. Zifaneleke ngokukodwa kwiindawo zokusetyenzwa apho ii-workpieces kufuneka zitshintshwe rhoqo.

3.Ukufunxa okuzinzileyo kuqinisekisa ukuchaneka kokulungiswa

I-chuck yamagnetic esisigxina inika amandla afanayo kunye nozinzile, ukuthintela ngokufanelekileyo i-workpiece ukuba ihambe okanye ishukume ngexesha lokucubungula, ngaloo ndlela iphucula ukuchaneka kokusebenza kunye nokusebenza kakuhle. Ifaneleke ngokukodwa ukulungiswa okuchanekileyo.

4.Gcina iindleko zendawo

Ngenxa yokungabikho konikezelo lwamandla kunye neenkqubo zolawulo ezintsonkothileyo, iichucks ezinamandla zemagnethi ezisisigxina zidla ngokuyilwa ukuba zibe compact ngakumbi, zizenze zilungele indawo zokusebenza ezinendawo encinci. Ngaphezu koko, iindleko zabo zokugcina eziphantsi kunye nobomi benkonzo ende bunokunciphisa ngokufanelekileyo iindleko zokuvelisa ngokubanzi.

5.Iguquguqukayo kakhulu, ilungele ii-workpieces ezahlukeneyo

I-chuck enemagnethi esisigxina ayinakukwazi ukuphatha kuphela izinto zentsimbi zesiNtu, kodwa ikwazi ukuziqhelanisa neemilo ezahlukeneyo kunye nobukhulu bezinto zokusebenza. Iyakwazi ukulungisa izinto zetsimbi ezityebileyo nezingaqhelekanga, ihlangabezana neemfuno ezahlukeneyo zokusetyenzwa. (Ngokuyinxenye, useto lwepoli yemagnethi enokwenzeka ngokwezifiso zicwangciswe ukuba zixhaswe)

III. Izicelo eziThintelweyo ze-High-Intensity Permanent Magnetic Chuck

Nangona i-chuck enemagnethi enamandla esisigxina inezicelo ezininzi kwimveliso yemizi-mveliso, abasebenzisi kusafuneka baqaphele ezi zithintelo zilandelayo xa bezisebenzisa, ukuze bathintele umonakalo wesixhobo okanye ukusebenza kakubi.

1.Kuphephe ukuvezwa ixesha elide kumaqondo obushushu aphezulu.

Amaqondo obushushu aphezulu aya kubangela ukuba iimpawu zemagnethi zemagnethi ezisisigxina zibe buthathaka ngokuthe ngcembe. Ngokukodwa kwiimagnethi zomhlaba ezinqabileyo ezisebenza kakhulu, ukuba sesichengeni ixesha elide kwindawo engaphaya komgangatho wobushushu obusebenzayo kunokukhokelela ekunciphiseni amandla okufunxa. Ke ngoko, i-chuck enemagnethi eyomeleleyo esisigxina kufuneka iphephe ukusetyenziswa kwiindawo zokusebenza ezinamaqondo obushushu aphezulu kakhulu.

2.Kuphephe ukudibana nemithombo enamandla yamagnetic

Ichuck yemagnethi eyomeleleyo esisigxina sele inamandla ombane owomeleleyo ngokwawo. Ukuba idibana nomthombo onamandla wemagnethi, inokubangela ukuba amandla emagnethi ehle okanye yonakalise ikomityi yokufunxa. Kuyafuneka ukuba kuqinisekiswe ukuba i-chuck eyomeleleyo yemagnethi esisigxina igcinwe kude nezixhobo ze-electromagnetic, izixhobo ze-frequency ephezulu, njl.

3.Kuphephe ukudibana ngqo nezinto ezidlekayo

Imichiza eyonakalisayo efana neeasidi ezomeleleyo kunye neziseko ezomeleleyo zinokuchaphazela umphezulu we-magnetic chuck esisigxina, ibangele ipropathi yayo yemagnethi yehle okanye yonakaliswe. Ngexesha lokusebenza, kuyimfuneko ukuphepha ikomityi yokufunxa ukuba idibane ixesha elide nezi zinto, ngakumbi ezo zingenawo amanyathelo okukhusela.

4.Kuphephe ukuNxibelela kwiSicelo

Nangona i-chuck enemagnethi enamandla esisigxina ibonelela ngamandla amakhulu okufunxa, ikwanawo nomda wokuthwala. Ukusetyenziswa ngokugqithisileyo kunokukhokelela ekuthotyweni kwemagnethi kunye nomonakalo kwisakhiwo se-chuck, kubeka umngcipheko wokhuseleko. Ngoko ke, xa usebenzisa, ubunzima obufanelekileyo bomsebenzi kufuneka bukhethwe ngokusekelwe kwiinkcukacha ze-chuck.

IV. Iindlela zoLondolozo lwe-Chuck yeMagnetic enamandla eZisigxina

Ugcino olululo alunakwandisa ubomi benkonzo kuphelaichuck enemagnethi esisigxina enamandla, kodwa kwakhona ugcine umphumo wayo wokubambelela. Nazi iindlela eziqhelekileyo zokulondoloza:

1.Ukucoca rhoqo

Umphezulu we-chuck kufuneka uhlambuluke rhoqo ukukhusela ukuqokelela kweentsimbi zetsimbi, i-oyile okanye enye inkunkuma. Oku kubaluleke ngakumbi ngexesha lokulungiswa kwesinyithi. Ungacoca umphezulu usebenzisa umoya ocinezelekileyo okanye ilaphu elithambileyo. Akukhuthazwa ukuba kusetyenziswe izinto ezinzima ukuyikhuhla, njengoko oku kunokonakalisa imagnethi.

2.Khangela rhoqo umazibuthe

Nangona i-chucks esisigxina yamagnetic ingathembeli kumthombo wamandla wangaphandle, amandla abo omagnetic asaya kuba buthathaka ngokuthe ngcembe njengoko ixesha lokusetyenziswa lisanda. Kuyimfuneko ukujonga rhoqo amandla okufunxa iikomityi zokufunxa ukuqinisekisa ukuba zihlala kwinqanaba eliqhelekileyo. Ukuba amandla okufunxa ancitshiswe kakhulu, kufuneka kuthathelwe ingqalelo ekutshintsheni iimagnethi okanye ukwenza ulondolozo.

3.Kulumkele ukungqubana ngobundlobongela

Imagnethi kwichuck enemagnethi esisigxina ibuthathaka. Iimpembelelo ezimandundu zinokubangela ukuba iimagnethi zophuke okanye amandla kazibuthe angasebenzi. Ngethuba lokusebenza, umntu kufuneka aqaphele ukuphepha ukungqubana okungadingekile.

Iichuck enemagnethi esisigxina enamandla, kunye neenzuzo zayo ezinjengokungabikho kwemfuneko yombane, ukufakwa ngokukhawuleza kunye nokuqhaqha, kunye namandla okufunxa okuzinzileyo, uye waba sisixhobo esiyimfuneko kwimveliso yanamhlanje. Ngokusetyenziswa okufanelekileyo kunye nokugcinwa, kunokwandisa kakhulu ukusebenza kakuhle kwemveliso kunye nokulungiswa kokuchaneka. Ukuqonda imigaqo yayo yobugcisa, iingenelo, kunye nokusetyenziswa okuchanekileyo kunye neendlela zokugcinwa kweyona nto ingundoqo ekuqinisekiseni ukusebenza kwayo kwexesha elide.

imathiriyeli yereferensi:

Itekhnoloji yeMagnetic Clamping-Isikhokelo kwiiclamp zemagnethi kunye nokusetyenziswa kwazo.

Imagnethi yoShishino-Iziseko zeemagnethi ezisisigxina ezisetyenziswa kwizixhobo zoshishino.

Qaphela: Iiparamitha ezithile zemveliso ziphantsi kolwazi lwamva nje olunikezwe ngumvelisi. Nceda undwendwele iziko lethu lemveliso ukuze ufunde ngakumbi malunga neemodeli okanye ucele ingxelo yokhetho!

Qhagamshelana nathi ukuze ufumane izisombululo ezilungiselelwe wena

Ixesha lokuposa: Aug-14-2025