I-Angle Head Holder

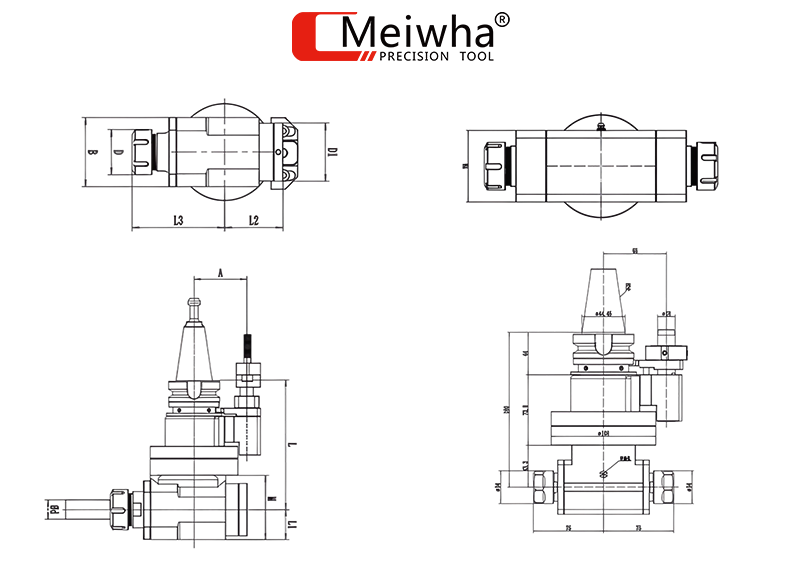

| Ikati.No | Uluhlu lokubamba | A | L | L1 | L2 | L3 | M | D | D1 | B | |

| BT/BBT30 | -AMER25-130L | 2.0-16.0 | 50 | 130 | 23 | 49 | 81 | 62 | 42 | 64 | 46 |

| BT/BBT40 | -AMER20-160L | 2.0-13.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 |

| -AMER25-160L | 2.0-16.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-160L | 2.0-20.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER40-160L | 2.0-26.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-160-2 | 3.0-20.0 | -- | 160 | 65 | 130 | 260 | -- | 108 | 50 | 74 | |

| BT/BBT50 | -AMER20-170L | 2.0-13.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 |

| -AMER25-170L | 2.0-16.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-170L | 2.0-20.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER40-170L | 2.0-26.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-170-2 | 3.0-20.0 | -- | 170 | 80 | 142 | 284 | -- | 108 | 63 | 74 | |

Isicelo somphathi we-engile:

1. MeiwhaI-Angle Head Holderisetyenziswa xa kunzima ukulungisa ii-workpieces ezinkulu, xa ii-workpieces ezichanekileyo zilungiswa ngexesha elinye kwaye i-polyhedron ifuna ukusetyenzwa, xa ilungiswa kuyo nayiphi na i-engile enxulumene nomphezulu wereferensi.

2. Ukucutshungulwa kugcinwa kwi-angle ekhethekileyo yokugaya i-profling, njenge-ball end milling, ezinye izixhobo azikwazi ukungena emngxunyeni ukucubungula umngxuma omncinci ngaphandle kwe-Meiwha Angle Head Holder.

3. Imingxuma e-Obligue kunye ne-grooves engakwazi ukuqhutyelwa yi-machining center ngaphandle kwe-Meiwha Angle Head Holder, njengemingxuma yangaphakathi ye-injini kunye ne-casing.

Imigqaliselo yomphathi we-engile:

1. Iintloko ze-angle ngokubanzi zisebenzisa izitywina zeoli ezingadibanisiyo. Ukuba amanzi okupholisa esetyenziswa ngexesha lokusetyenzwa, kufuneka asetyenziswe phambi kokuba kutshizwe amanzi, kwaye icala lombhobho wamanzi okupholisa kufuneka lidityaniswe ukuze kutshizwe amanzi kwisixhobo ukunqanda amanzi apholisayo ukuba angangeni emzimbeni. Ukuze bandise ubomi.

2. Gwema ukuqhubeka nokusebenza ngokuqhubekayo kwisantya esiphezulu ixesha elide.

3. Jonga kwiimpawu zeparameter zentloko ye-angle yemodeli nganye kwaye uyisebenzise phantsi kweemeko ezifanelekileyo zokucubungula.

4. Ngaphambi kokusetyenziswa, kufuneka uqinisekise ukuba uvavanyo luqhuba imizuzu embalwa ukufudumala injini. Ngalo lonke ixesha uqhuba kufuneka ukhethe isantya esifanelekileyo kunye nesondlo sokuqhubekeka. Isantya, isondlo, kunye nobunzulu bokusikwa ngexesha lokulungiswa kufuneka luhlengahlengiswe ngendlela kude kufumaneke ubuninzi bokusebenza

5.Xa iprosesa ngentloko ye-angle eqhelekileyo. kuyimfuneko ukuphepha izinto zokucubungula eziza kuvelisa uthuli kunye neengqungquthela (ezifana negraphite, carbon, magnesium kunye nezinye izinto ezidibeneyo, njl.)

Side Milling Series

Meiwha90° Side Milling Head

Inokugcinwa kwimagazini yesixhobo, Ukutshintsha isixhobo esizenzekelayo, ukugaya okuchanekileyo

Ukuqina okuphezulu kweTorque enkulu

Xa udibana nezixhobo ezinobunzima obuphezulu ngexesha lokucubungula, intloko ye-angle inokugcina ngcono ukuchaneka kunye nokujikeleza okuzinzile.

Isixhobo esizenzekelayo siTshintsho oluchanekileyo lokugaya

Uyilo olulula, olukwazi ukutshintsha isixhobo esizenzekelayo ngokugcinwa kwimagazini.

Indlela yokufakela i-angle yomphathi wentloko

I-Angle Head Classification

Uhlobo Lwesakhiwo:

Imveliso enye, imveliso emibini, imveliso ye-quad, i-adjustable, inclined, offset nonstandard.

Uhlobo lokuBamba:

Uhlobo lwe-Collet, uhlobo lwesibambi, uhlobo lwe-clamping esecaleni, uhlobo lokugaya ubuso.

Uhlobo lokuhlohla:

Uhlobo lwesibiyeli olusisigxina, uhlobo lweflange, uhlobo lweplate yekhonkco ye-latin.

Umsebenzi weNtloko ye-engile

I-1.Precis workpieces, ukubeka ixesha elilodwa, umatshini onamacaleni amahlanu, ukuqinisekisa ukuchaneka.

I-2.Ii-workpieces ezinkulu, i-multi-face processing, ukuphucula ukusebenza kakuhle.

3.Yenza ukusetyenzwa kwayo nayiphi na i-engile kwindawo ethambekeleyo, ii-engile okanye imingxunya.

4.Umngxuma ngaphakathi komngxuma: unokwenziwa ngoomatshini kusetyenziswa i-offset, iintloko ze-angle ezitsolo ezisixhenxe.

5.Iigrooves ezimxinwa kunye negrooves ethambekeleyo inokwenziwa ngoomatshini kusetyenziswa i-offset universal angle heads.